FAQ

Precautions for use:

- The upper jaw of the test lead must make extremely firm contact with the breaker’s outgoing terminal; therefore use a bucket truck, clamp from an elevated position, and secure the lead to the terminal with a short rope for best results.

2. Because graphite-contact breakers are usually old, the outgoing terminals and conductors on both sides of the gap are heavily oxidized. Polish them lightly with abrasive cloth; a thick oxide layer will make the data unstable.

3. Testing principle:

Apply a 20A DC constant current source to the fracture of the graphite contact circuit breaker, and calculate the closing and opening time by collecting the voltage changes at both ends of the fracture at high speed. When the circuit breaker is closed, the graphite contact comes into contact with the metal static contact first, and this time is the closing time. However, during this and subsequent movement, the graphite metal contact resistance is unstable. It is not until the metal contact at the back of the graphite contact comes into contact with the metal static contact that the contact resistance drops to a relatively stable value. The instrument collects voltage changes on the fracture surface to determine the metal metal contact time (a metal metal contact threshold voltage needs to be set, generally set to 20mV), and then calculates the graphite contact closing time or opening time based on the length of the graphite coating and the measured closing and opening speed or rated closing and opening speed.

合闸计算方法:

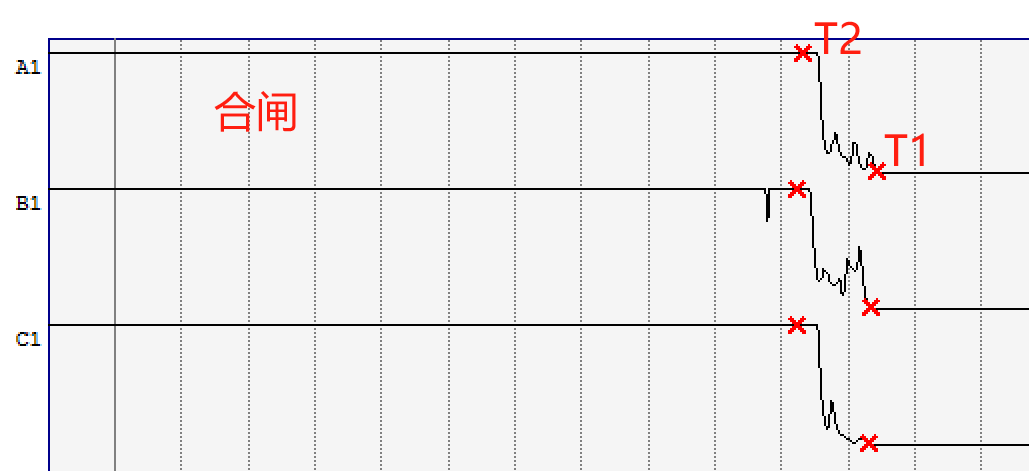

As shown in the figure above, when the switch is closed, the instrument tests for the metal metal contact time (T1), and T2 for the graphite metal contact time (just closed time)

Then: T2=T1- graphite length/closing speed

Opening calculation method:

机翻 · 通用领域

As shown in the above figure, the time for instrument testing is the metal metal contact time (T1), and T2 is the graphite metal separation time (just after separation time)

Then: T2=T1+graphite length/opening speed